Calcining zinc oxide is a precise and essential process that plays a pivotal role in various industries. In this article, we will unravel the intricacies of calcining zinc oxide, focusing on the production process, material considerations, and the significance of choosing top-notch suppliers for a seamless supply chain.

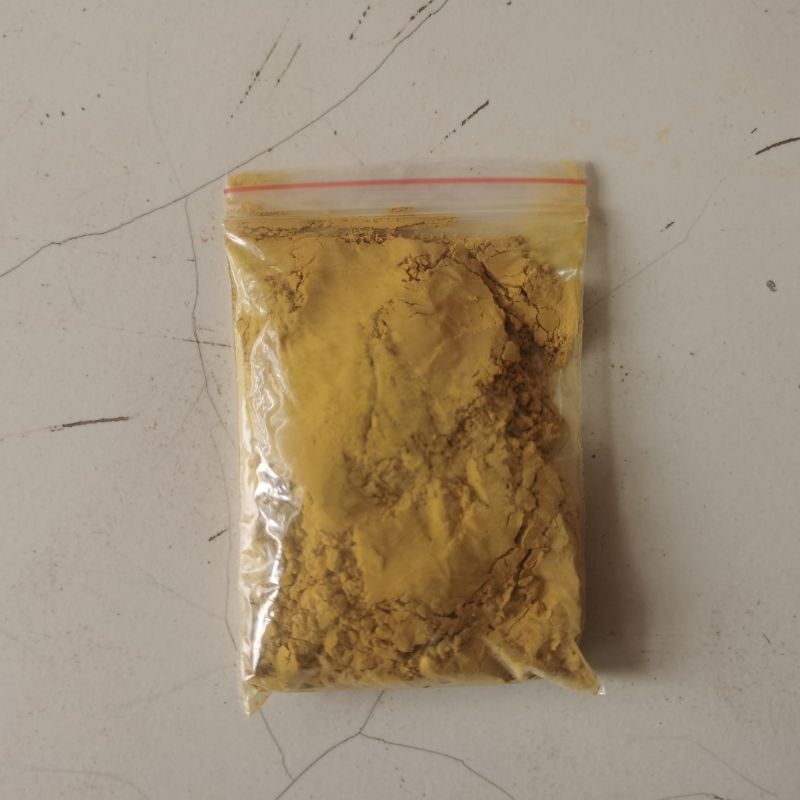

Calcining zinc oxide involves the thermal decomposition of zinc carbonate or zinc hydroxide compounds. This process is typically carried out in a high-temperature furnace, where zinc oxide is obtained by driving off carbon dioxide or water. The controlled calcination process ensures the purity and quality of the final product, making it suitable for diverse applications.

The quality of calcined zinc oxide is directly influenced by the choice of raw materials. High-grade zinc carbonate or zinc hydroxide is crucial for achieving a superior end product. Suppliers who prioritize the sourcing of premium materials contribute significantly to the success of the calcination process. This ensures that the resulting zinc oxide meets industry standards and customer expectations.

Choosing the right wholesalers for calcined zinc oxide production is imperative for industries relying on this essential compound. Reputable wholesalers specialize in providing a seamless and reliable supply chain, ensuring that the calcination process is supported by top-quality materials. Wholesalers play a vital role in maintaining consistency and meeting the demands of various industries.

Leading makers in the industry contribute to the excellence of calcined zinc oxide production. Their expertise lies not only in the calcination process but also in developing innovative methods to enhance efficiency and quality. Makers focus on refining the production techniques, ensuring that the calcined zinc oxide meets stringent standards and serves as a reliable component for diverse applications.

The supply chain for calcined zinc oxide production is a critical aspect that impacts the accessibility and affordability of the product. Suppliers who master the supply chain dynamics ensure a steady flow of materials, efficient production processes, and timely delivery. This is particularly crucial for industries where calcined zinc oxide is a fundamental ingredient.

mastering the calcination process of zinc oxide requires a comprehensive understanding of the production process, material quality, and a reliable supply chain. Wholesalers and makers specializing in calcined zinc oxide play a vital role in delivering a superior product that meets the diverse needs of industries. Elevate your industry by partnering with top suppliers who excel in every aspect of calcined zinc oxide production, ensuring the success of your applications.